The DP45N and DP31-422VABD Hiller Decapress centrifuges are now available as standard built packaged plants, which means minimal on site build time.

MSE Hiller’s new DP45N and DP31-422 machines, which cover capacities from 1 to 25 m3/hr, can now come pre-built as a complete ‘Decasmart’ dewatering plant with all necessary ancillary components already connected.

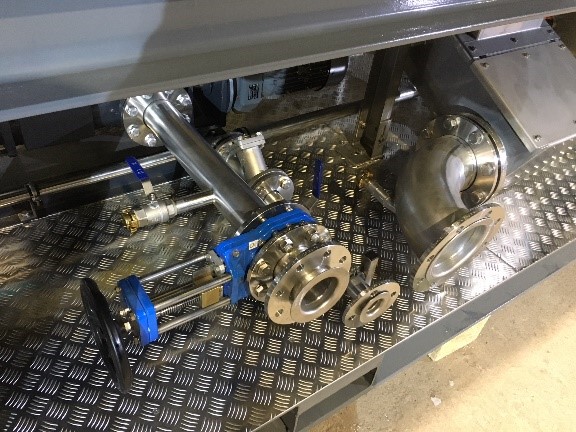

Components of the new packaged skid mounted Decasmart centrifuge systems include:

Building most of the centrifuge infrastructure as a packaged plant enables the unit to be pre-built off site at Hiller’s workshops. Once delivered and on-site, the pre-built plant is simply connected to local site services before being fully operational. Site installation and connection typically takes between just three and four hours.

The new units also boast a standard size footprint of 5.6 m x 2.2 m enabling them to fit in a 20 ft container, allowing them to be easily containerised for overseas shipping.

For further information and details about MSE Hiller’s packaged skid mounted Decasmart centrifuge systems, contact our team on 01246 861166 or email nfo@mandse.com or message us here

MSE Hiller, Harper Way, Markham Vale

Chesterfield, Derbyshire. S44 5JX.

MSE Hiller is a trading name, registered at companies house as Mobile & Separation Equipment Limited. Co. Reg 4194135

Copyright 2019 MSE Hiller | All Rights Reserved | Privacy / Cookie Policy | Web Design by CNS Media.